What will Earth look like in the near future? Consider: In 2019, we generated 53.6 million tons of electronic waste, according to the U.N.’s “Global E-waste Monitor 2020.” This desert of garbage was 21% larger than five years ago, and it is getting bigger every year.

In recent years, awareness has grown tremendously concerning the perils facing our planet, but now is the time for companies that generate industrial waste to take decisive action. The display industry is no exception, and LG Display has been doing its part.

LG Display’s war on waste

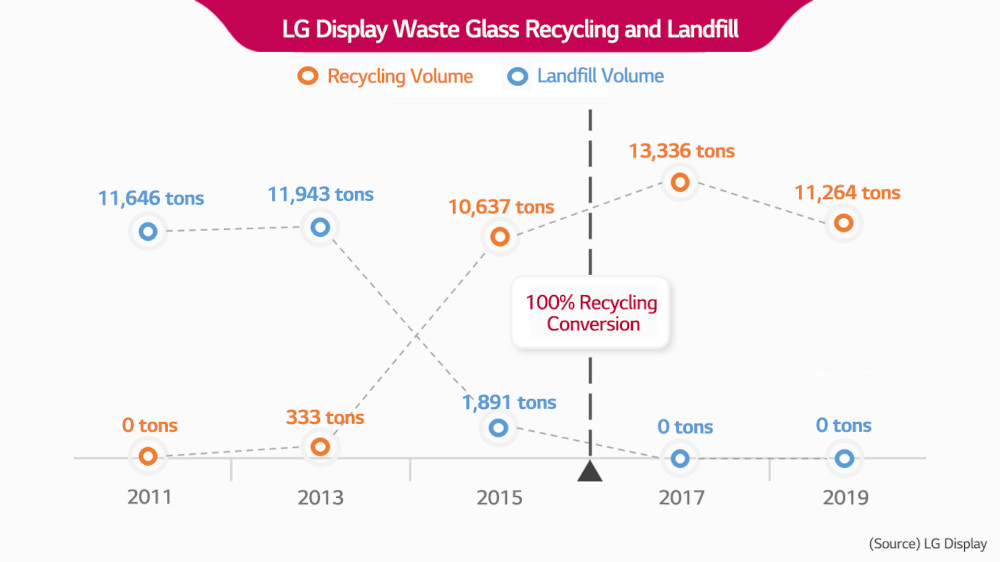

One of the important breakthroughs for LG Display in this battle has been reducing the amount of waste glass produced by the display manufacturing process. When the company found its existing shredder was plagued with breakdowns and damage it partnered with waste companies to develop a new and more efficient type of shredder. As a result, the company has produced zero waste glass since 2017 – down from a high of 11,943 tons in 2013 – and increased the amount of waste glass it recycles from zero in 2011 to 11,264 tons in 2019.

There have been some financial benefits along the way, too. As of 2019, waste glass treatment costs had dropped by KRW 1.9 billion per year, while the cost of waste disposal had also been reduced by around KRW 110 million on an annual basis.

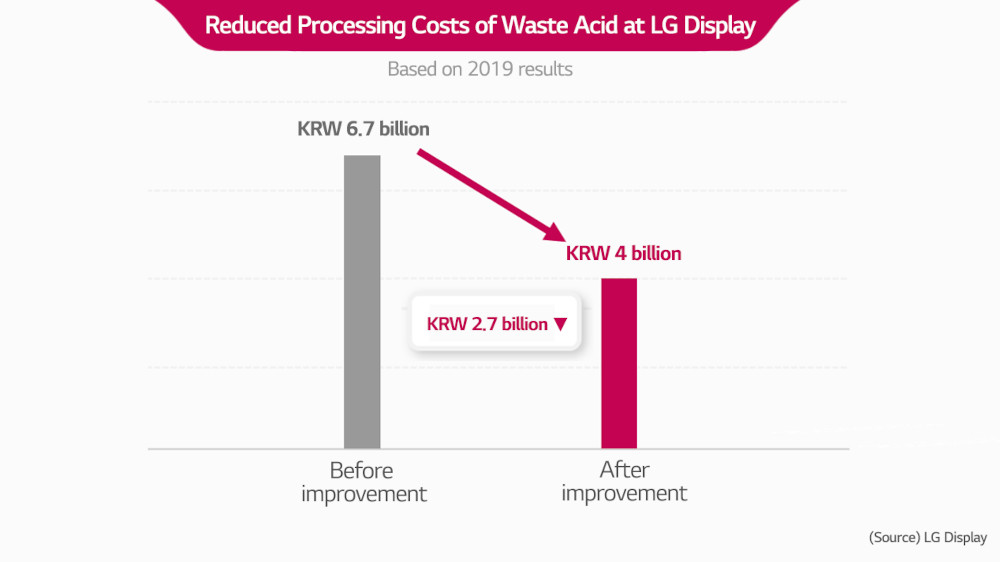

LG Display has also made strides to reduce liquid industrial waste by cutting the volume of chemicals used in the manufacturing process. By 2019, this resulted in a 3,735-ton, or 67%, decline in annual acid waste production – worth KRW 2.7 billion a year in reduced treatment costs. In addition, an improved treatment system has allowed annual recycling of 3,964 tons of waste acid, saving a further KRW 3 billion.

Meanwhile, the company has been recycling other items that used to be thrown away when they were found to be faulty. For example, when wooden pallets used in the export process are scratched or otherwise damaged, they have to be immediately withdrawn to avoid possible damage to the products they are carrying. Now, instead of discarding them, LG Display redeploys them for in-factory transport. This program was saving 70 tons of pallets a year as of 2019.

LG Display additionally recycles synthetic resins and packaging materials. This has involved an upgraded collection process and partnership with a specialist recycling company tasked with the separation and discharge of the various kinds of waste.

Employees for the environment!

Both executives and employees alike at LG Display have been actively participating in these recycling efforts.

Not only in the field but also in the office, waste has been classified into six types. Throwing garbage in the right place has become part of the company’s daily work life. But staff are also continually finding ways to improve, as evidenced by a campaign to reduce the use of paper cups and other strategies to recycle resources.

In recognition of these achievements, LG Display’s Paju production hub was recently selected as the “2020 Leading Recycling Company and Outstanding Performance Workplace,” receiving a commendation from South Korea’s Minister of Environment. LG Display has also been selected as a member of the “Carbon Management Honors Club” for three years running and an “Excellent Water Management Company” for two years in a row by the international non-profit Carbon Disclosure Project (CDP).

If the lush greenery surrounding the company’s Paju plant is anything to go by, perhaps there is a greener future ahead of us after all.